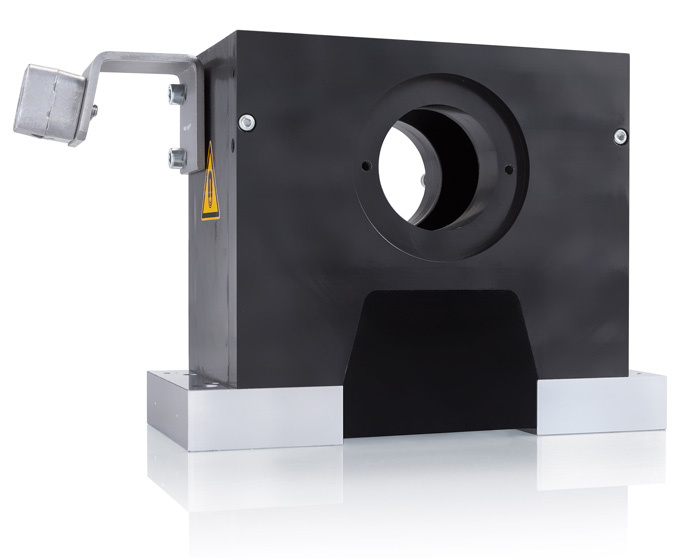

DEFECTOMAT DI

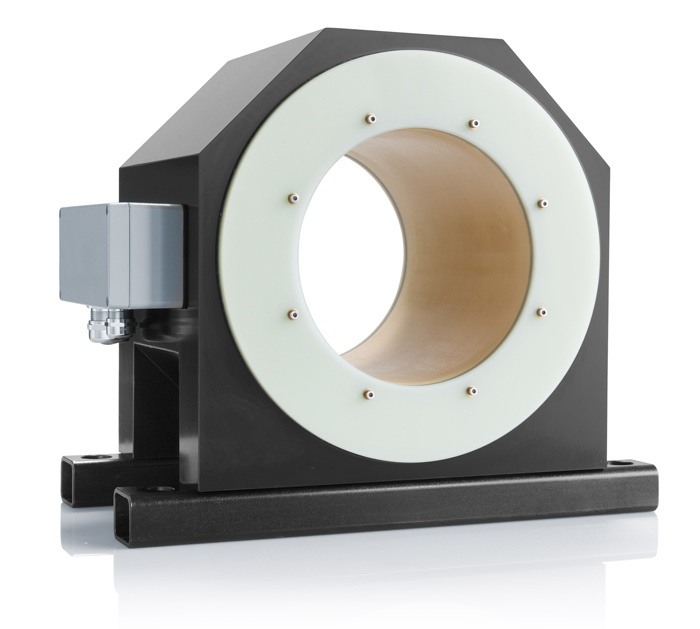

Compact entry level model for eddy current testing of long products such as tubes, rods, wire, and profiles

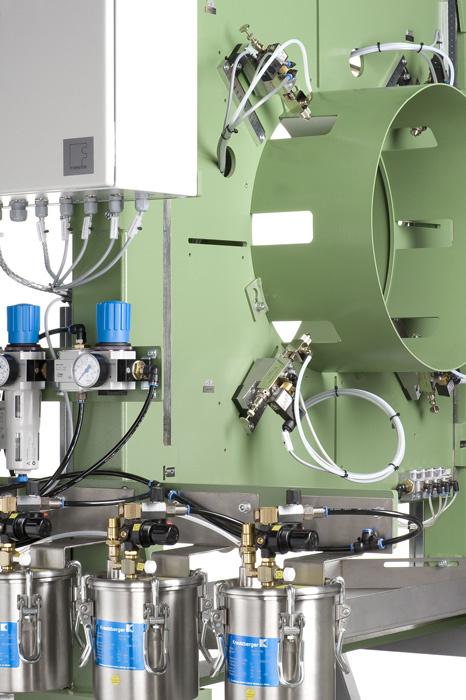

Structured quality assurance made simple. The DEFECTOMAT DI has the same comprehensive features as the DEFECTOMAT CI less integrated operation unit. An external computer connected via Ethernet performs all operation, administration, and archiving. tasks. The module's deceptively plain design hides a multitude of functions that make it easy to use the system electronics in almost any production environment.

Product highlights

Technical information

| Measurement channels: | Max. 2 independent channels, differential or static operation, second measurement channels optionally as FERROMAT |

| Excitation frequencies: | 1, 3, 6, 10, 12, 15 20, 30, 60, 100, 300, 1,000 kHz (optional additional frequencies) |

| Filtering process: | manual, 25 levels, 1 Hz – 16 kHz |

| Amplification: | max. dynamic range 102 dB |

| Test speed: | max. 150 m/s |

| Sensor monitoring: | disruption, short circuit, overload |