Crack Inspection

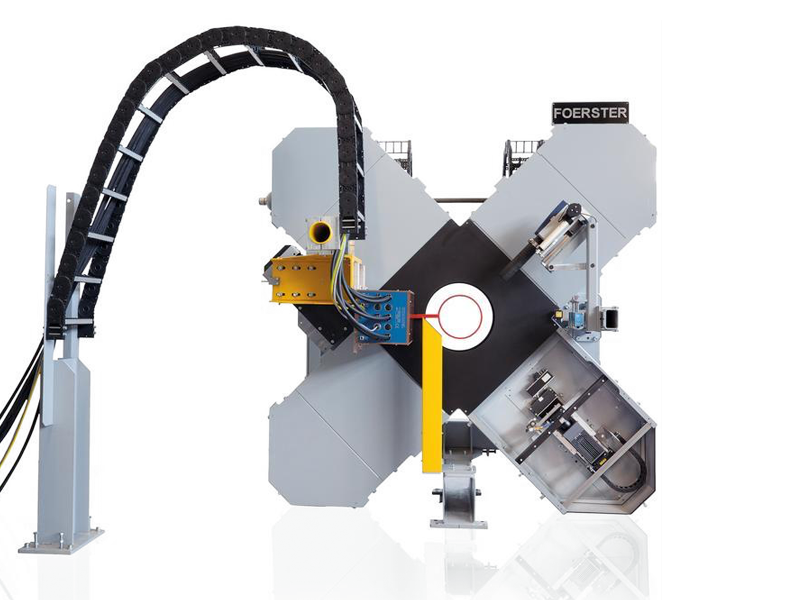

Surface defects such as cracks, pores, or inclusions can compromise the strength, performance, and safety of materials and components. FOERSTER testing systems enable reliable, non-destructive crack detection – from semi-finished products to finished parts, across various materials and geometries.

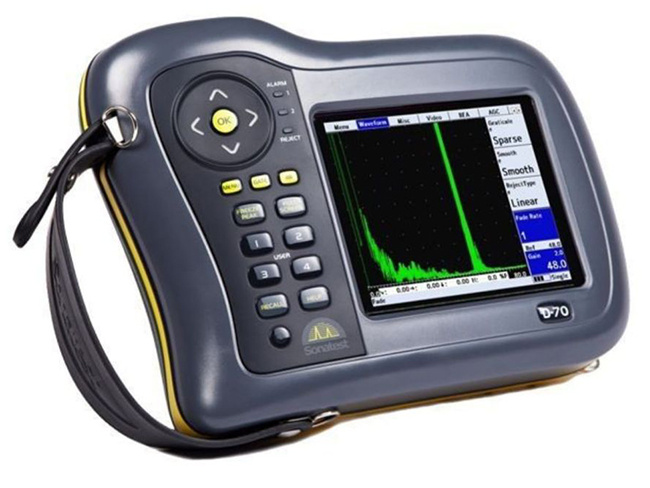

Cracks can occur during forming, heat treatment, or machining processes and must be detected early to prevent failures. FOERSTER offers advanced testing solutions for identifying longitudinal, transverse, and point defects on metallic surfaces – without damaging the component. Depending on the application, technologies such as eddy current testing, flux leakage, or heat flow thermography are used. Fully automated systems ensure efficient inline inspection in production, while mobile testing devices allow precise on-site measurements during maintenance. Combined with decades of experience and a wide sensor portfolio, FOERSTER provides tailor-made solutions for every crack detection challenge – ensuring maximum safety and quality in industrial manufacturing.