DEFECTOMAT DA

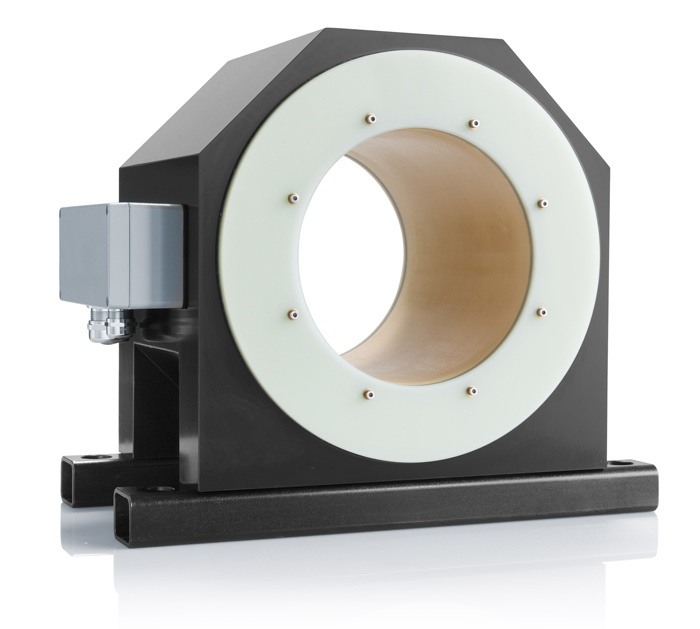

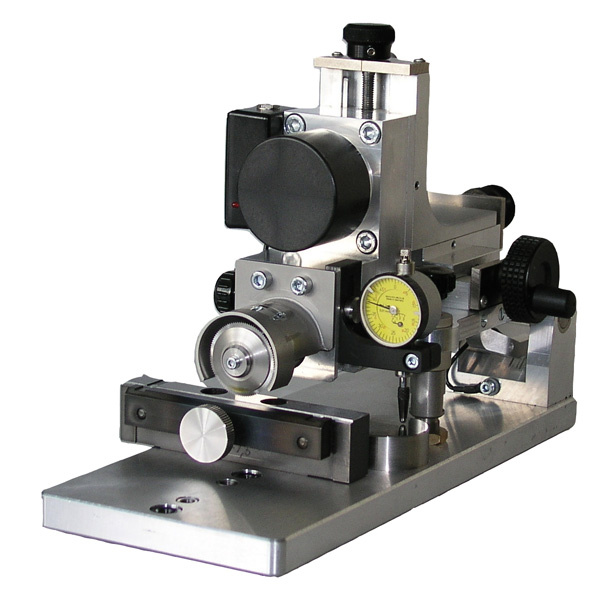

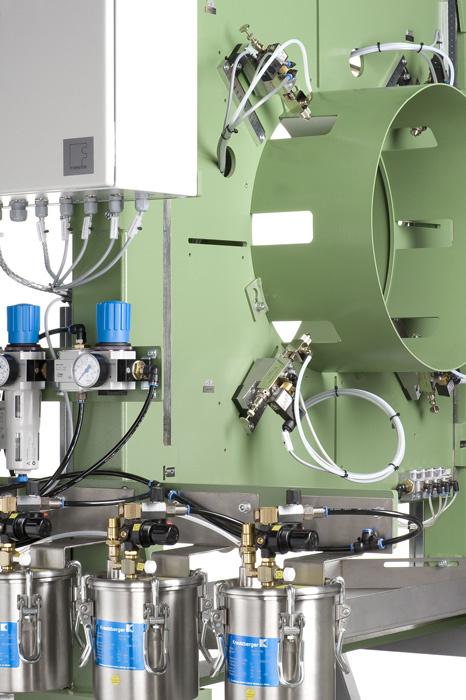

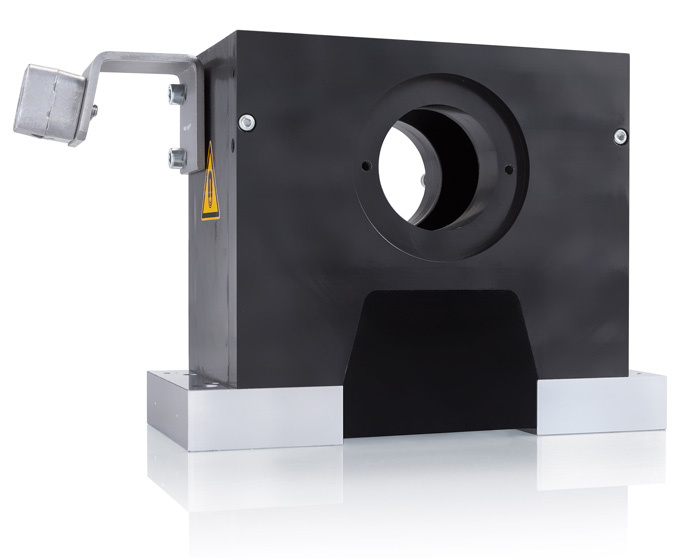

New level of development of eddy current testing of long products such as tubes, rods, wire, and profiles

A new definition of premium class. The DEFECTOMAT DA evaluation electronic equipment by FOERSTER has a combination of key features that as a whole are designed to provide consistent productivity and process reliability. Fully digital and fitted with innovative operating software, this system with unequalled specifications combines the latest technology for non-destructive eddy current testing of tubes, rods, and wires. Experience the eddy current technology of the future today.

Product highlights

Technical information

| Measurement channels: | Up to 16 TEST SYSTEM DA modules with 16 measurement channels each, optionally for differential probes, clearance probes, and Ferromat probes |

| Excitation frequencies: | 1 kHz - 1 MHz (endlessly adjustable) |

| Filtering process: | Digital speed shift filter; filters move along dynamically with the speed |

| Testing speed: | max. 150 m/s |

| Amplification: | max. dynamic range 126 dB |

| Sensor monitoring: | Broken wires, overload, automatic sensor recognition |

| Patent | The DEFECTOMAT DA uses processes patented to Institut Dr. Foerster GmbH & Co. KG, including US 8907828 B2 "METHOD AND DEVICE FOR TESTING THE MATERIAL OF A TEST OBJECT IN A NONDESTRUCTIVE MANNER". Also protected in many other countries worldwide. |