Topend inspection

Where critical cracks often begin. FOERSTER’s TopEnd Inspection detects internal thermal fatigue damage in the upper sections of reformer tubes – areas traditionally left uninspected. Using a specialized eddy current probe with rotating ID scan, even fine cracks can be identified early, preventing tube failures, fires, and costly production losses.

Historically, in-service inspections of reformer tubes have focused on the heated sections inside the furnace. However, experience from modern steam methane reformers (SMR) has revealed a hidden risk: cracks forming in the top ends of the tubes, caused by thermal fatigue. These internal defects originate on the inside surface and propagate outward – typically without any measurable creep – making them invisible to conventional inspection methods.

Failures in these top-end zones can have severe consequences. A crack that goes unnoticed may lead to tube rupture, fire, and cascading damage to neighboring tubes, pigtails, or structural steel. Because these areas are rarely accessible, such incidents can remain undetected until major production losses occur.

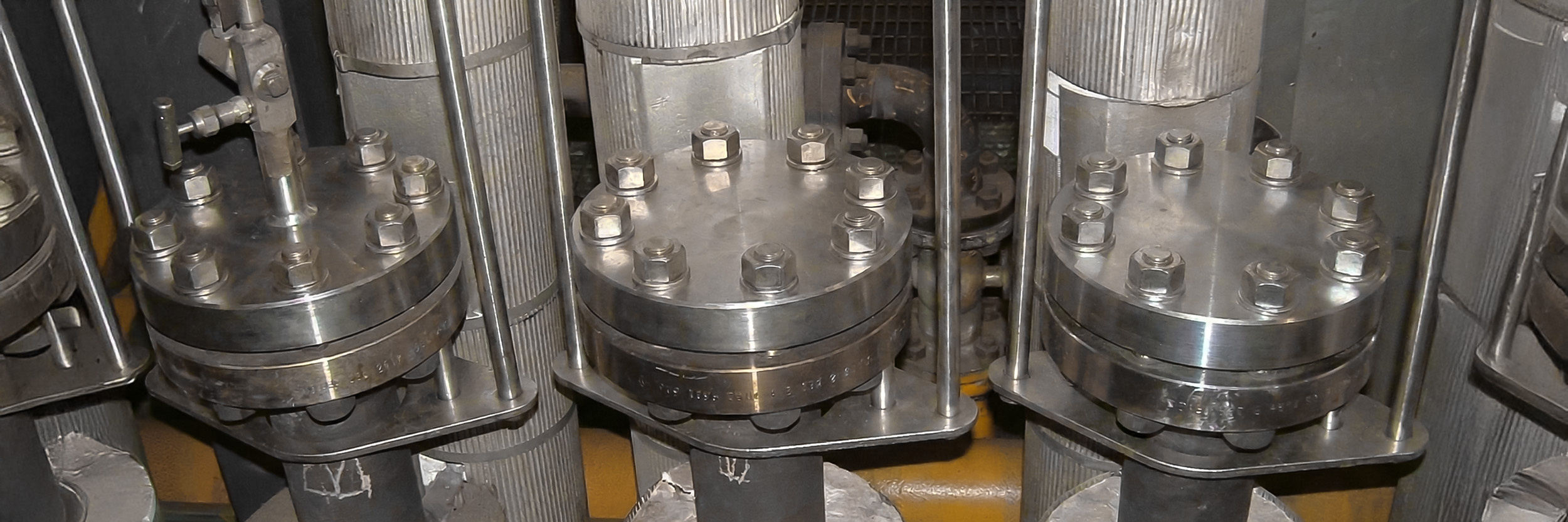

To counter this risk, FOERSTER developed a reliable inspection technique using a purpose-built eddy current probe for rotating ID scans of the tube top ends. This method detects cracks, fatigue fissures, and related defects before they reach the outer wall. The results are displayed in a color-coded C-scan, providing a clear visualization of the crack size, location, and orientation.

The inspection delivers repeatable, high-resolution data, allowing maintenance teams to monitor defect growth over time and take preventive measures. Early identification of thermal fatigue cracks not only ensures safe, dependable operation, but also protects valuable assets and minimizes unplanned downtime.

With FOERSTER’s TopEnd Inspection, operators gain full visibility into a previously overlooked critical area – securing plant reliability, efficiency, and safety.