Test defect saw

Precision sawing of artificial test errors for calibration

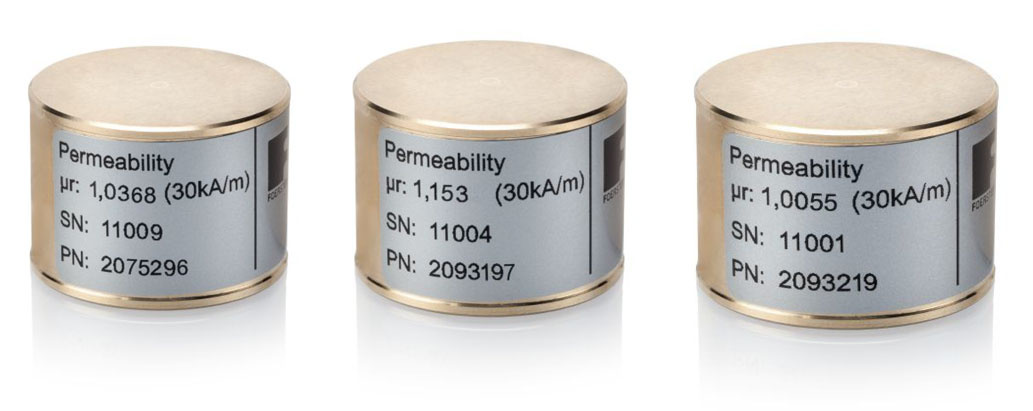

Practical solution for including external defects. To ensure compliance with high quality requirements, international standards such as EN 10246 define artificial test defects. For this purpose, FOERSTER offers a precision test-defect saw that enables standardized and reproducible defect depths for artificial longitudinal and transverse flaws.

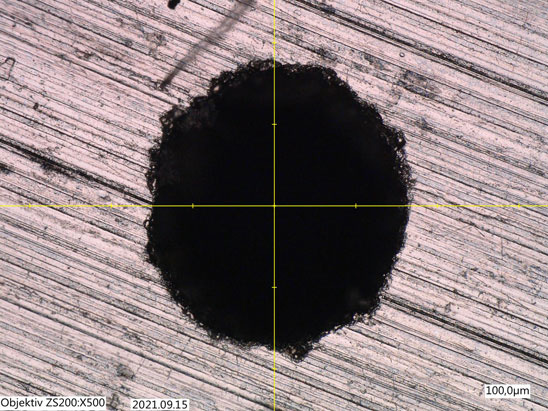

The fine increments of the twist-clamping sets allow optimal clamping of the test materials and precise zero-point adjustment (when the saw blade first touches the material). This ensures a cutting accuracy of 10 µm.

Product highlights

Technical information

| Test material: | Metallic wires, tubes, and rods |

| Range of diameters: | 1 – 20 mm |

| Motor speed: | 200 rpm with HSS switch position, 600 rpm with HM switch position |

| Saw blade strengths (groove width): | 0.08 – 0.1 – 0.2 – 0.3 mm |

| Maximum groove length: | 25 mm |

| Longitudinal cut accuracy: | 100 μm |

| Depth cutting accuracy: | 10 μm |

| Saw blade material: | HSS – HM |