Component testing

Every component must meet strict requirements for safety, function, and durability. FOERSTER testing technologies verify the structural integrity and material identity of parts used in vehicles, aircraft, power plants, and medical devices. Non-destructive testing detects cracks, hardness variations, or material mix-ups early – ensuring that critical components perform reliably in every application.

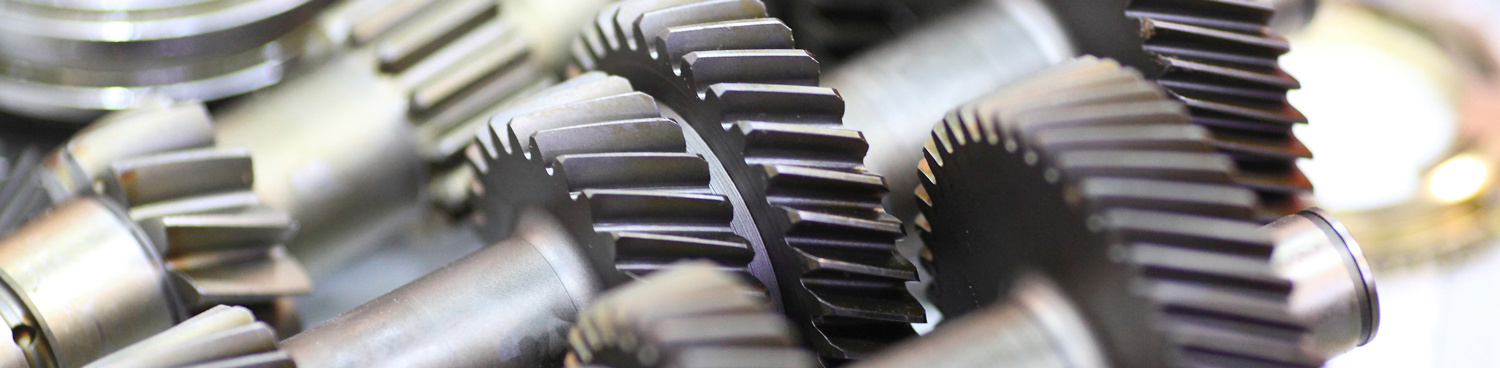

Drive train

The drive train transmits the engine’s power to the wheels and is one of the most heavily stressed systems in a vehicle. Its key components—such as coupling, gears, and drive shafts—must function in perfect harmony and meet the highest material and manufacturing standards.

Combustion engine

The combustion engine is the heart of every vehicle or aircraft, converting fuel into motion through complex mechanical interactions. Because many of its components are safety-relevant, materials such as pistons, valves, and camshafts must meet the highest quality standards.

Undercarriage and steering

The undercarriage and steering system form the foundation for driving stability and safety. They contain numerous safety-relevant components such as brake discs, control arms, and steering parts that must meet the highest quality and reliability standards.

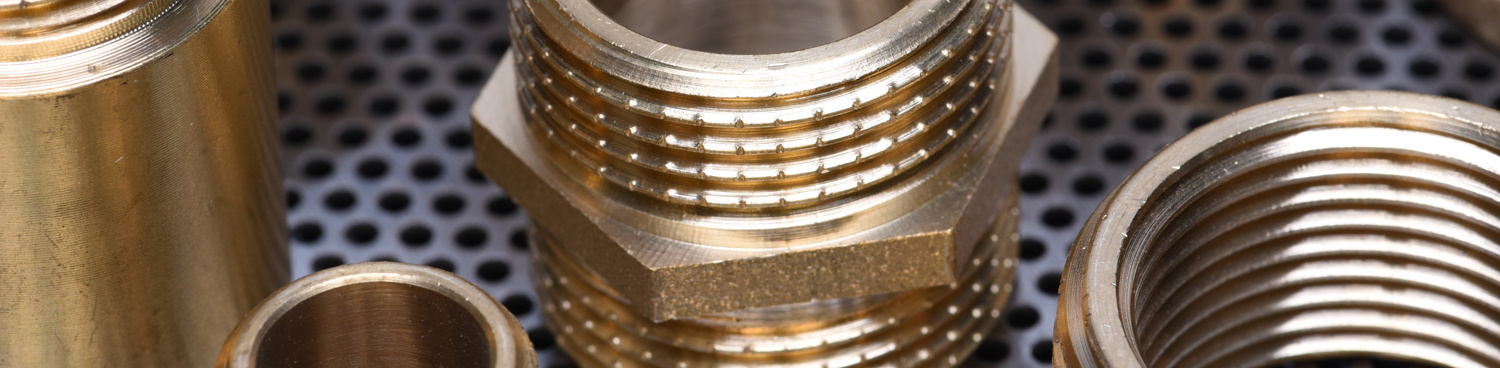

Connecting components

Connecting components such as screws, bolts, and tube fittings are often small and inconspicuous, yet they play a critical role in ensuring the safety and functionality of vehicles and aircraft. Their reliability depends on the material quality, which must be thoroughly tested and verified.

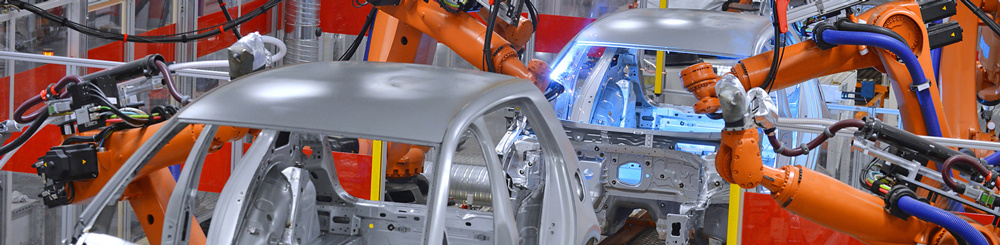

Vehicle Bodywork / Outer skin

Vehicle bodywork is typically made of steel or aluminum sheets, while aircraft outer skins are constructed from lightweight aluminum or aluminum alloys. These structures are joined with rivets and must meet the highest standards for strength, surface quality, and material integrity.

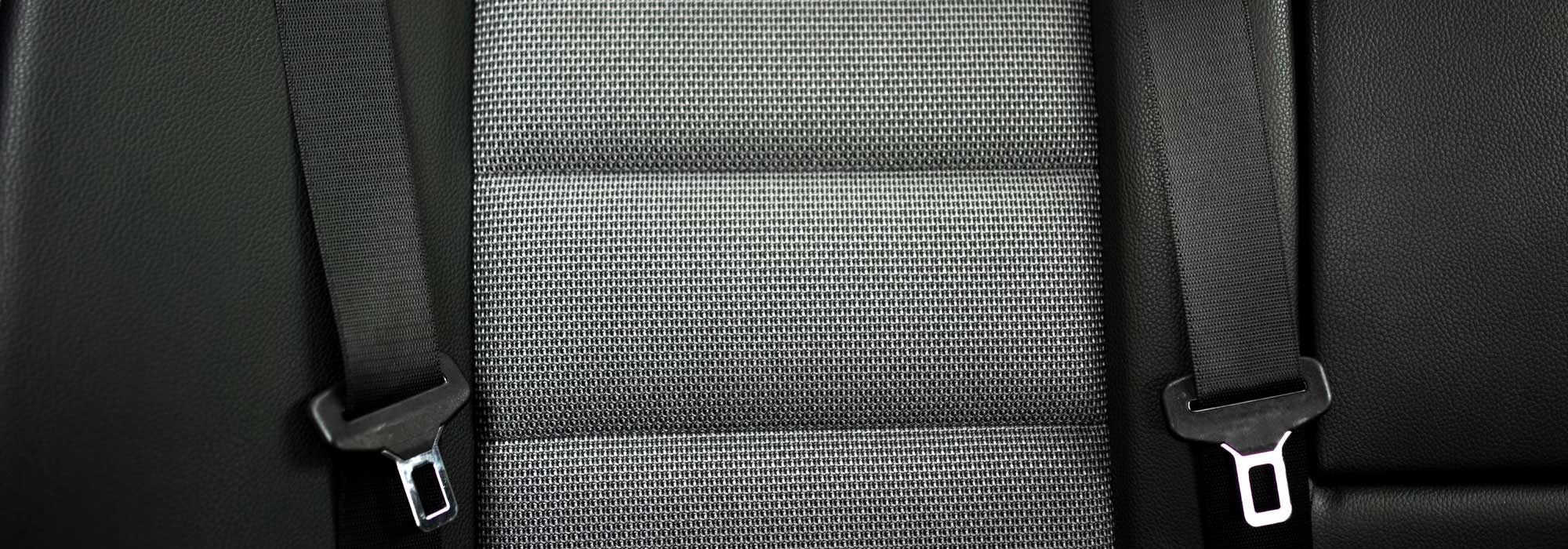

Interior

Even inside vehicles and aircraft, FOERSTER technology ensures safety and reliability. Components such as seat belt clips, airbag tubes, and seat structures are tested for cracks, material mix-ups, and hardness to meet strict safety standards.

Power plant technology

Power plant and aircraft turbines are exposed to extreme thermal and mechanical stresses. To ensure safe and efficient operation, components such as turbine blades and housings must be tested for cracks, corrosion damage, and material mix-ups during manufacturing and maintenance.

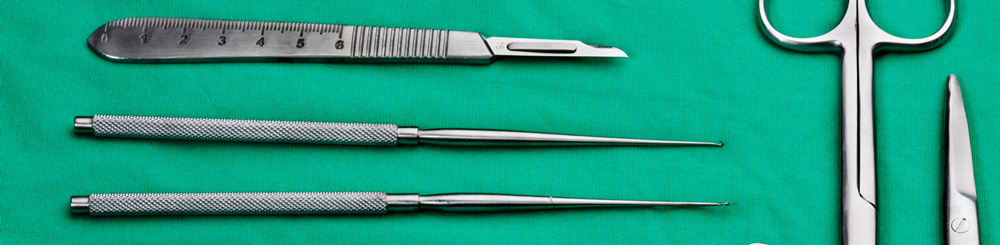

Medical technology (component testing)

Medical technology demands maximum precision and reliability in every production step. Metals such as medical-grade steel, titanium, or platinum must meet the highest material standards to ensure the safety and performance of surgical instruments and implants.