FOERSTER Test Systems develops turnkey solutions for the automated, non-destructive testing of semi-finished metallic products. Combining decades of mechanical design expertise with advanced sensor and software technology, FOERSTER delivers complete testing lines for tubes, bars, wires, and profiles. From electromagnetic and ultrasonic inspection to smart automation and intuitive software control, every FOERSTER system ensures precise detection, seamless operation, and measurable quality in production.

Featured products

Integrated testing technology for highest production quality

Comprehensive testing expertise

The FOERSTER Business Unit Test Systems (TS) provides complete solutions for surface and volumetric inspection of semi-finished products. Our modular systems integrate seamlessly into rolling mills, drawing or welding lines, and finishing operations—ensuring continuous quality control in demanding production environments.

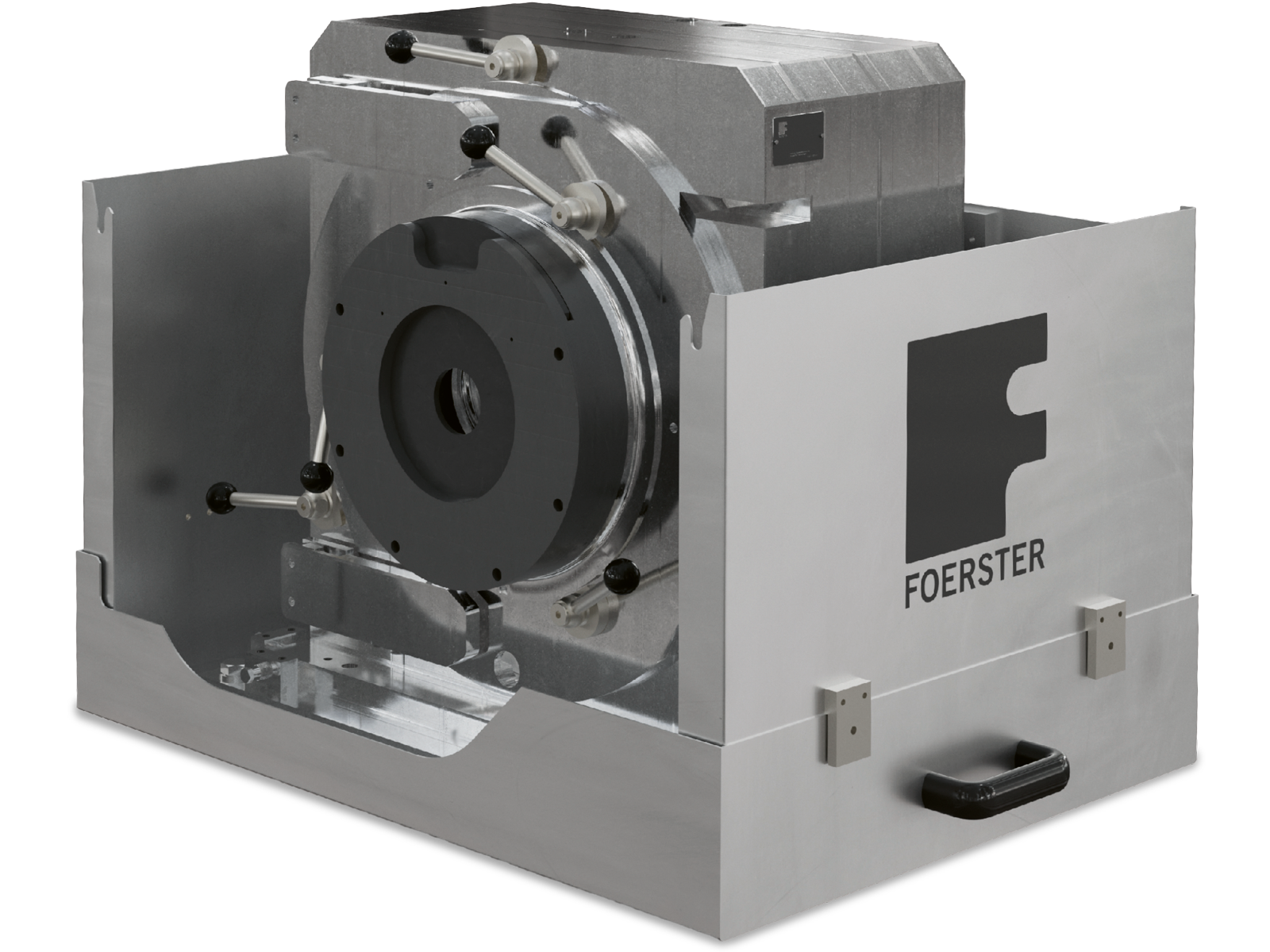

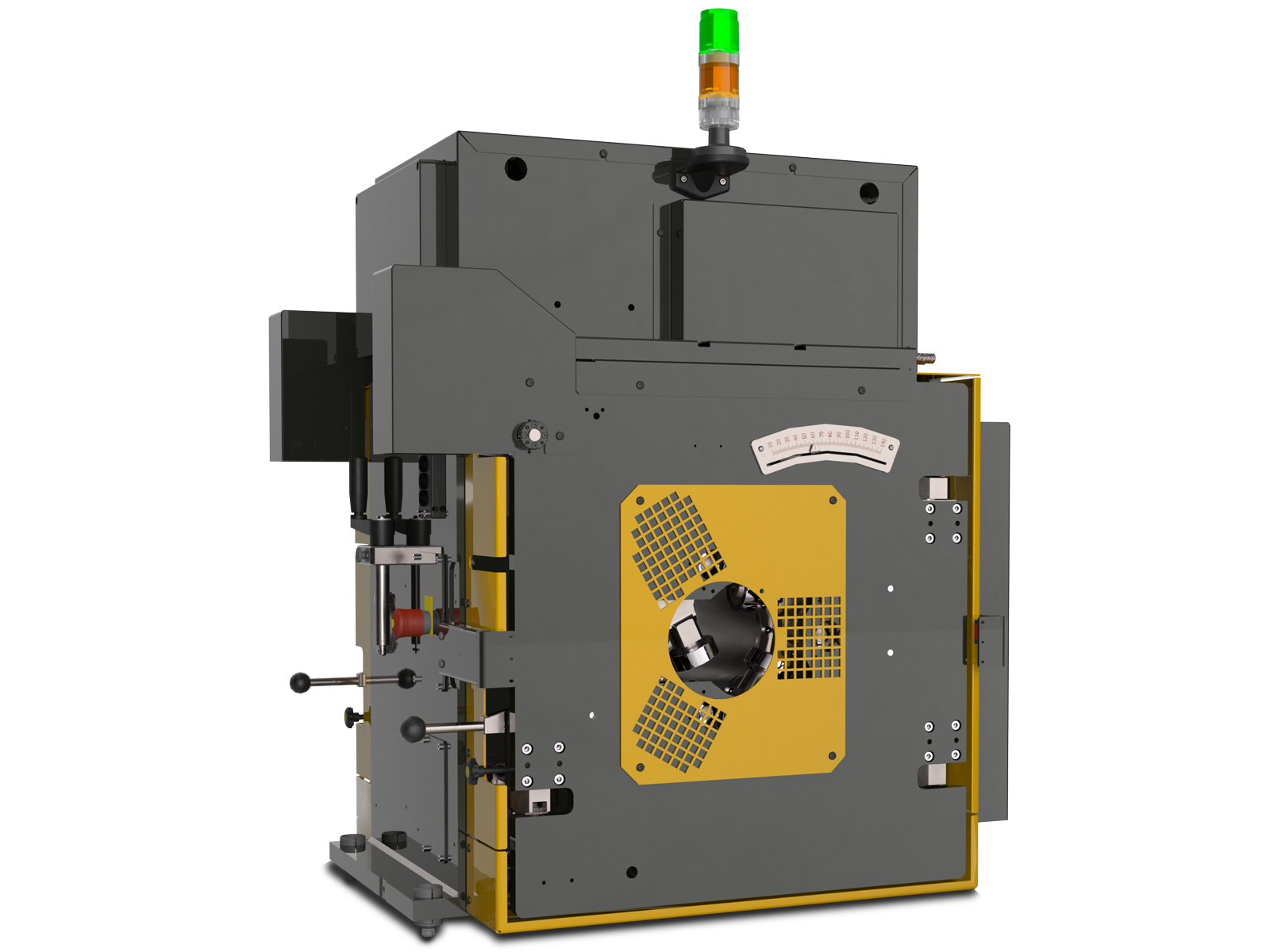

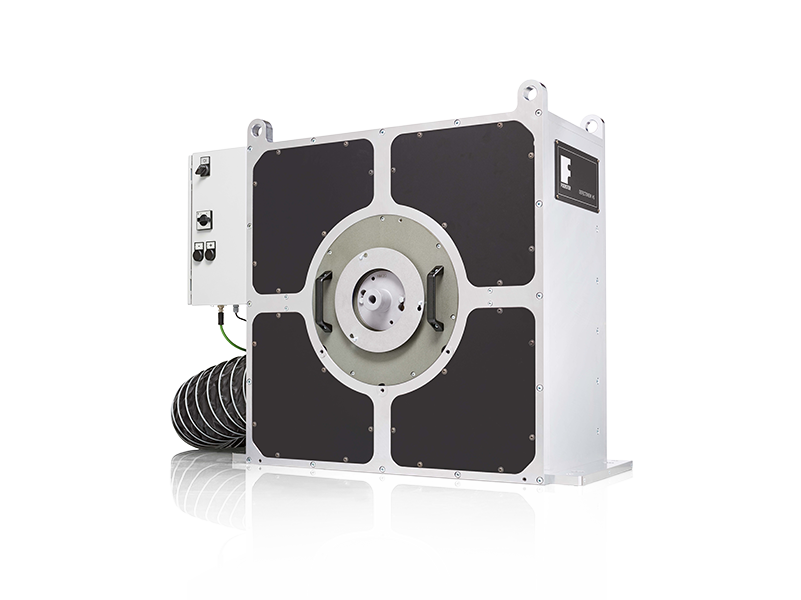

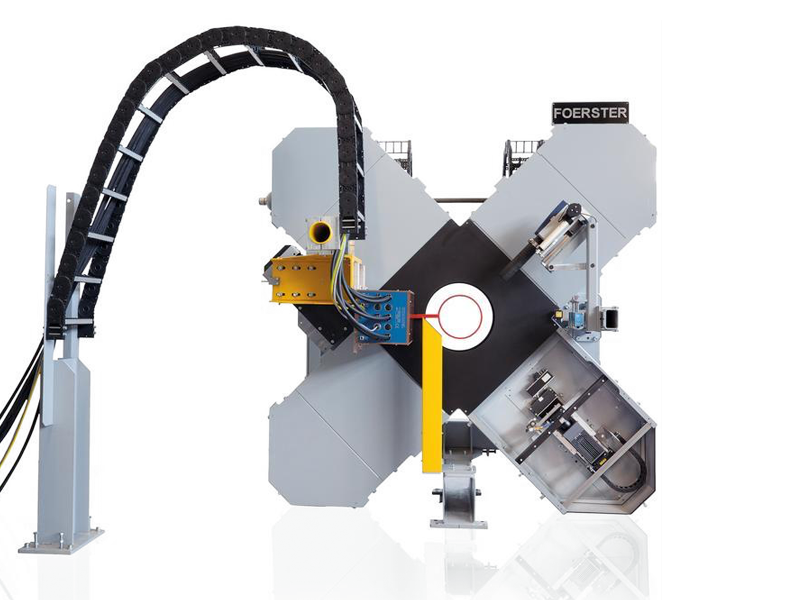

Products such as CIRCOFLUX DA for AC flux-leakage testing, CIRCOGRAPH Product Family and DEFECTOMAT Product Family for eddy-current inspection, and MAGNATEST D-HZP for material property testing deliver reliable, reproducible results at high throughput.

Automation and intelligent software

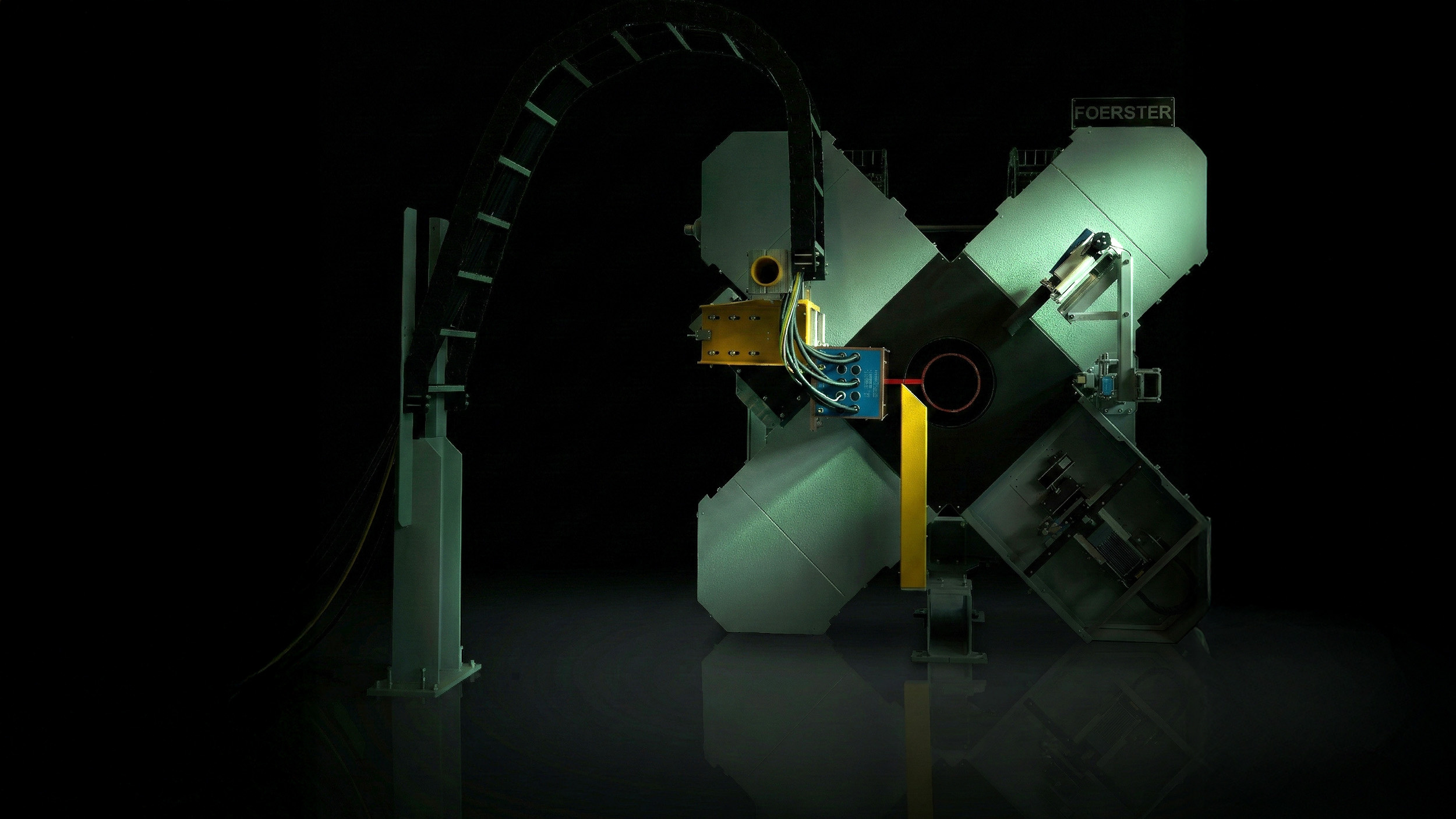

For customer-specific automation, FOERSTER designs tailored test lines using systems like ROTOMAT DA and TRANSOMAT DA, adaptable to various diameters and testing speeds. The Instrumentation Software coordinates all instruments—including third-party devices—through one central interface, enabling unified job management, synchronized data, and seamless connection to higher-level production control systems.

Intuitive operation and real-time insight

The Operation Software offers an intuitive GUI for direct instrument control with customizable multi-screen layouts. Together with the high-definition C-Scan visualization of the ROTOMAT/TRANSOMAT Product Family, it enables 360° detection of oblique and natural defects with high reproducibility—reducing manual re-inspection and improving process efficiency.

In bar and plate inspection, BARPROOF (phased-array ultrasonic) and PLATEPROOF or DEFECTOVISION IR extend FOERSTER’s expertise to complete ultrasonic and thermographic testing solutions.

Engineering excellence and global support

Decades of mechanical and electrical design experience ensure durable, maintenance-friendly test lines precisely matched to customer requirements. From concept to commissioning and service, FOERSTER acts as your single partner worldwide—providing expert training, technical support, and 24/7 assistance for maximum system uptime.