Flux leakage testing

Flux leakage testing is a non-destructive method for detecting surface and internal defects in ferromagnetic materials. By magnetizing the test object and measuring local field disturbances, the method reliably identifies imperfections before the material is further processed or installed.

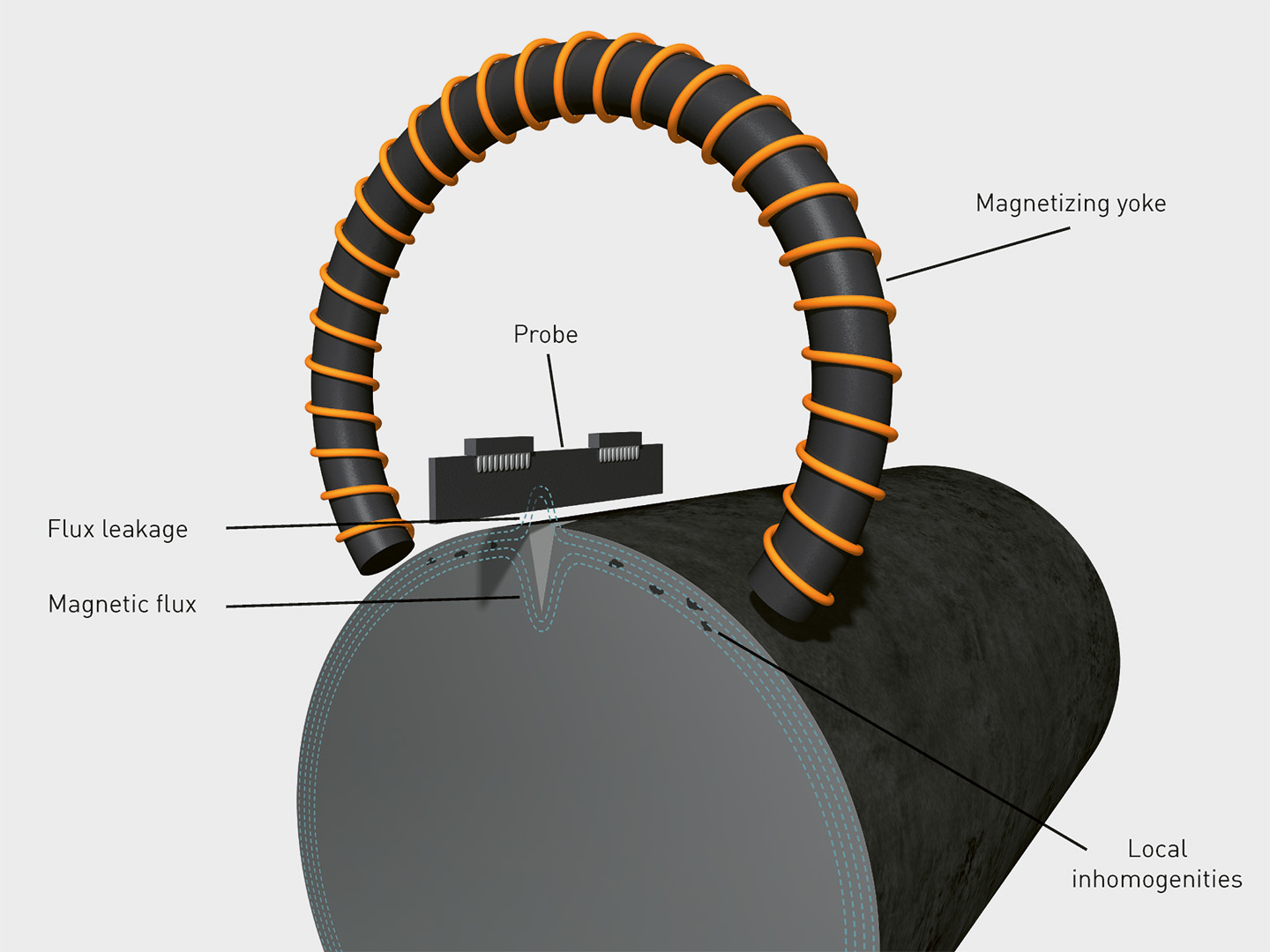

In magnetic flux leakage testing, a strong magnetic field is applied to magnetize ferromagnetic materials such as steel. In flawless areas, the magnetic flux flows uniformly through the material. Defects such as corrosion, pits, or wall-thickness variations disturb this flow, causing magnetic field lines to leak out at the surface.

Sensors positioned around the test object detect these magnetic leakages and convert them into measurable signals. The resulting data reveal the location, size, and orientation of flaws on both the inner and outer surfaces. This non-destructive testing method enhances safety and quality by identifying material defects early – before the components are further processed, installed, or subjected to operational stress. With its precision, speed, and reliability, flux leakage testing is a cornerstone of modern quality assurance in ferromagnetic materials.