Hardness/structure testing

Monitoring hardness and microstructure is essential to ensure that materials meet required performance and quality standards. FOERSTER testing systems enable fast, reliable, and non-destructive verification of material properties – directly in production or during maintenance.

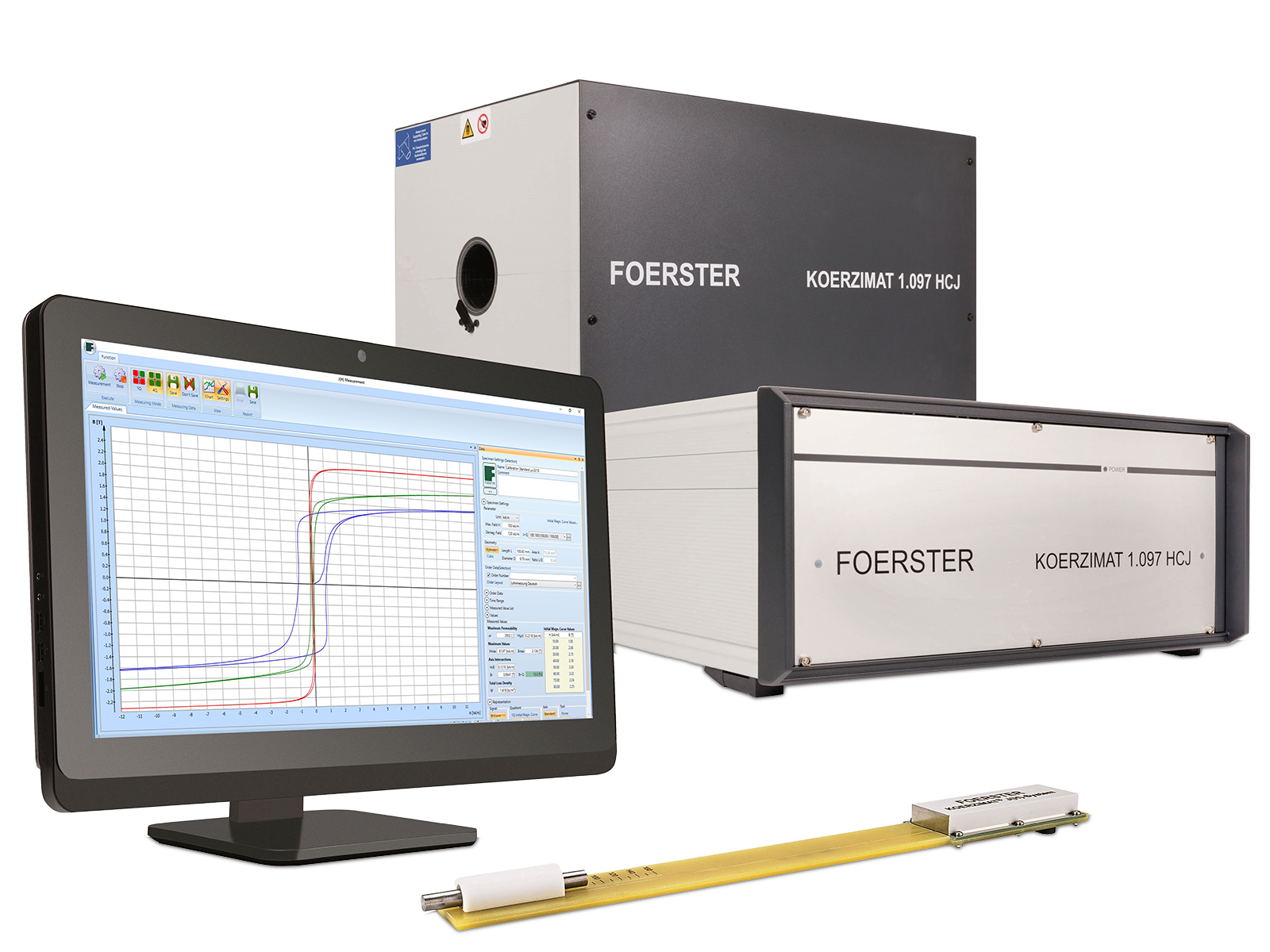

The mechanical properties of metals depend directly on their hardness and microstructure. Variations caused by heat treatment, alloying, or forming processes can affect strength, wear resistance, or function. FOERSTER testing systems use #eddy current and #magneto-inductive methods to assess these characteristics quickly and non-destructively. The technology enables the detection of deviations in hardness, structure, or material grade, as well as the verification of heat treatment results. Integrated into automated lines or used in mobile applications, FOERSTER solutions ensure consistent material performance and help prevent mix-ups or production errors. This combination of precision, speed, and reliability makes FOERSTER an essential partner for quality assurance in industrial manufacturing.