Marking of different defects with various colors. FOERSTER provides a color marking system for accurately and automatically marking defects found during surface testing. This system can easily be integrated in the existing test equipment.

The various defect types (such as longitudinal, transverse, external, and internal defects and various defect sizes) can be marked differently if required. Several units are combined and filled with various colors for this purpose.

Your advantages at a glance

Low maintenance single and multiple channel color coding Marking colors with different consistency can be used Precision marking of defects due to extremely short response time Defect types such as longitudinal, transverse, external, and internal defects can be marked using different colors

Nominal voltage for triggering the solenoid valve: 24 V ± 10% Air pressure at the filter regulator inlet: min. 4 bar, max. 8 bar Control air: min. 4 bar Nebulizer air: 2 to 4 bar Container pressure: 0.5 bar Spray gun type: PILOT Signier V 2036010083 (Walther) Color container type: V 4402130003, MDG2 (Walther) Storage time: max. 12 months (optional extension after interim inspection by FOERSTER personnel) Available colors: all commonly available marking colors with suitable drying times, including ink

Related products

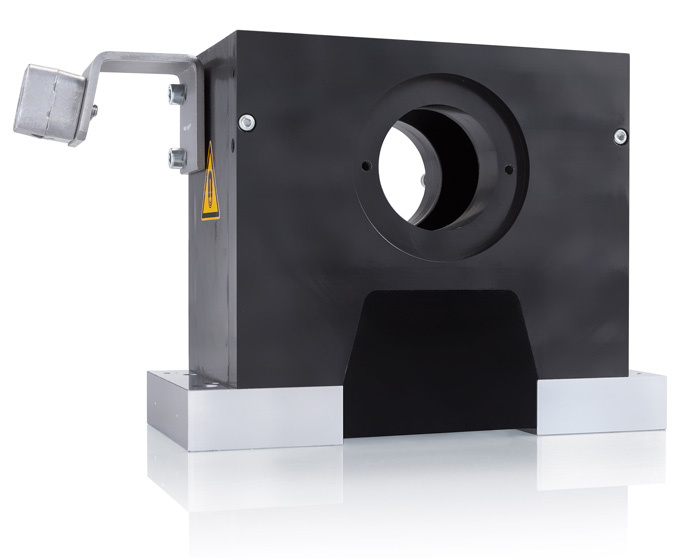

EMAG

Demagnetization unit for ferromagnetic wires, rods, and tubes

MAG

Magnetization supply for ferromagnetic wires, rods, and tubes

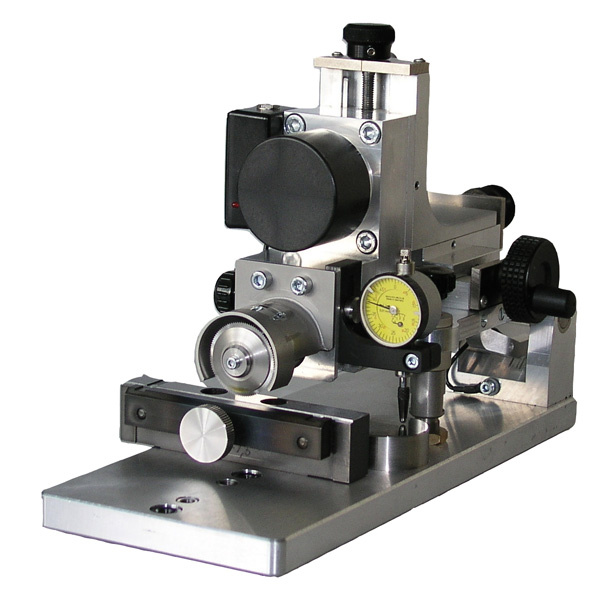

Test defect saw

Precision sawing of artificial test errors for calibration

DEFECTOMAT Sensor Systems

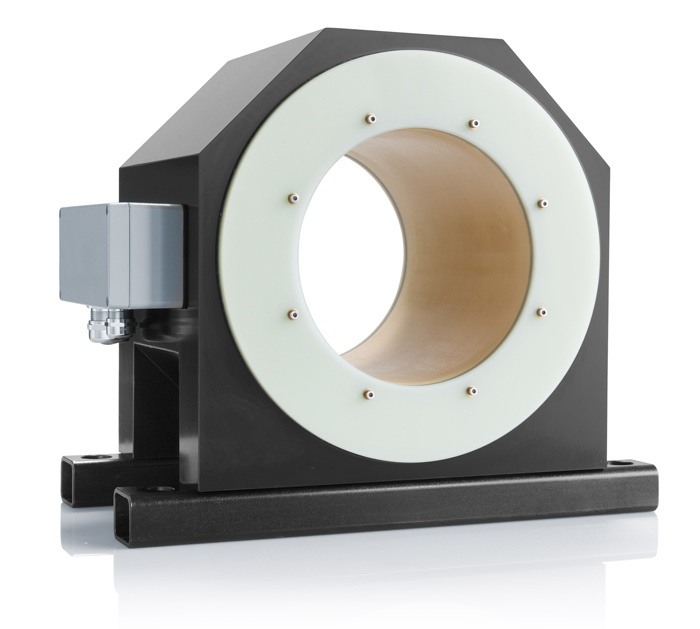

Sensor system H

For the eddy current testing of round and profiled non-ferromagnetic material with encircling coils

Sensor system M

For the eddy current testing of round and profiled ferromagnetic material with encircling coils and electrical dc-field magnetization

Sensor system P

For the eddy current testing of slightly ferromagnetic material with through-type coils and permanent magnetization

Sensor system S

Eddy current testing of weld seams

DEFECTOMAT sensor systems for small dimensions

Sensor systems for the eddy current testing of fine wires and tubes

DEFECTOTHERM

Eddy current sensor system with thermal coils for hot applications for wires, tubes, and rods