Identification checking

Mix-ups of materials can occur even in automated production processes. FOERSTER testing systems enable fast, non-destructive identification of material types to prevent costly errors, tool damage, or safety risks – ensuring that only the correct material enters the next production stage.

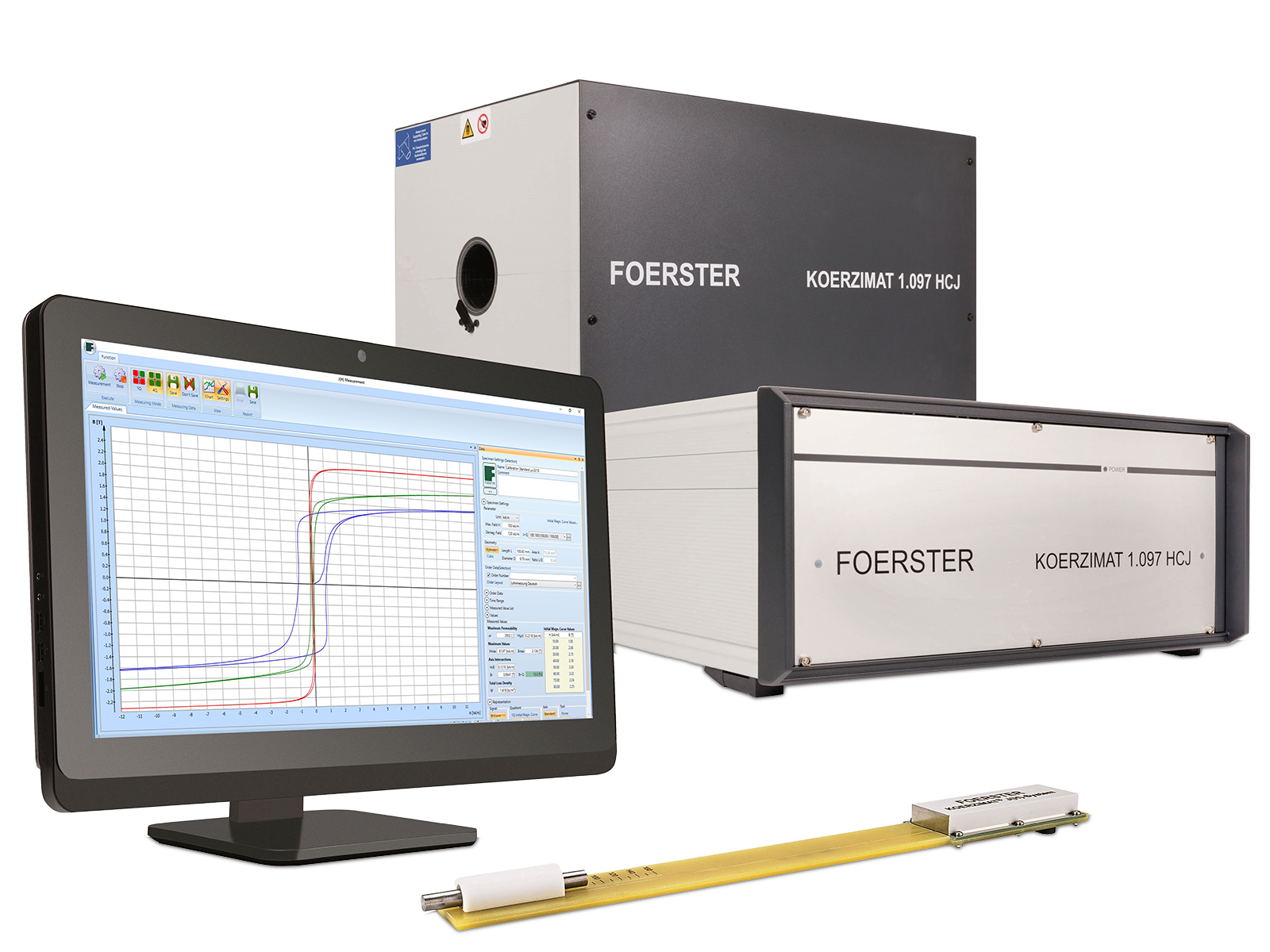

Material identification is crucial wherever similar-looking alloys or grades are processed. Even minor mix-ups can lead to production interruptions, defective parts, or functional failures. FOERSTER systems use #magneto-inductive testing methods to verify material properties such as alloy composition, hardness, or heat treatment condition. The test is fast, contactless, and suitable for both semi-finished products and finished components. Integrated into automated lines, the technology enables 100% inspection and immediate separation of incorrect parts. Combined with adaptable sensors and advanced evaluation algorithms, FOERSTER ensures reliable material verification in real time – for consistent quality and process safety in industrial manufacturing.