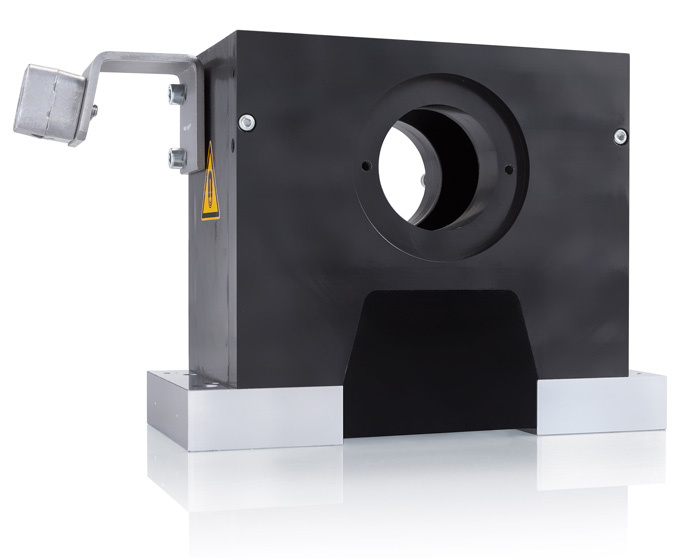

Eddy current testing of weld seams. Molded segment coils from 10 mm to 500 mm were developed for the eddy current testing of weld seams. The LSM segment coil yoke is used for ferromagnetic tubes. The magnetization strength can be adjusted to suit the test task. The LSP segment coil yoke can also be used if lower magnetization strength is sufficient.

Your advantages at a glance

Testing of austenitic, non-ferrite and ferrite metals Coils can be operated with the sensor systems LSP, LSM, or S. Suitable for weld seam testing The accompanying S sensor systems are fitted with a robust spindle system for height adjustment and adaptation to the testing line

Test material diameter:

10 mm – 180 mm or flat

Related products

DEFECTOMAT sensor encircling coil

Sensor for the eddy current testing of round or profiled material with encircling coil

DEFECTOARRAY

Segmented encircling coil for the eddy current testing of round or profiled material

DEFECTOMAT probes

Probes for non-destructive crack detection using eddy current

DEFECTOMAT weld seam probe with holder

Sensor for the partial eddy current testing of weld seams

Flex probes

Flexible probes for eddy current testing of complex geometries

DEFECTOTHERM coil

Water-cooled thermal coils for hot applications for wires, tubes, and rods

DEFECTOMAT Sensor Systems

Sensor system H

For the eddy current testing of round and profiled non-ferromagnetic material with encircling coils

Sensor system M

For the eddy current testing of round and profiled ferromagnetic material with encircling coils and electrical dc-field magnetization

Sensor system P

For the eddy current testing of slightly ferromagnetic material with through-type coils and permanent magnetization

Sensor system S

Eddy current testing of weld seams

DEFECTOMAT sensor systems for small dimensions

Sensor systems for the eddy current testing of fine wires and tubes

DEFECTOTHERM

Eddy current sensor system with thermal coils for hot applications for wires, tubes, and rods