Tube

Tube refers to hollow, cylindrical or profiled metal products manufactured through hot rolling, cold drawing, extrusion, or welding. Tubes combine low weight with high stability and are used for transporting fluids, structural applications, and precision components across industries such as automotive, oil & gas, energy, and HVAC. Their geometry and wall thickness place specific demands on non-destructive testing to ensure weld quality, surface integrity, and uniform material properties throughout production.

Bundy tubes

Bundy tubes are special double-sided steel tubes. They are highly stable under high pressure. Bundy tubes are therefore typically used as hydraulic brake pipes in the automotive sector.

Welded NFE / FE tubes

Tubes with thin walls compared to the outer diameter are usually produced as welded tubes. In most cases, the base material is a metal strip which is welded longitudinally.

Hot tubes

Hot tubes are all tubes that are hot-drawn in production. The high temperatures present the test systems with special requirements.

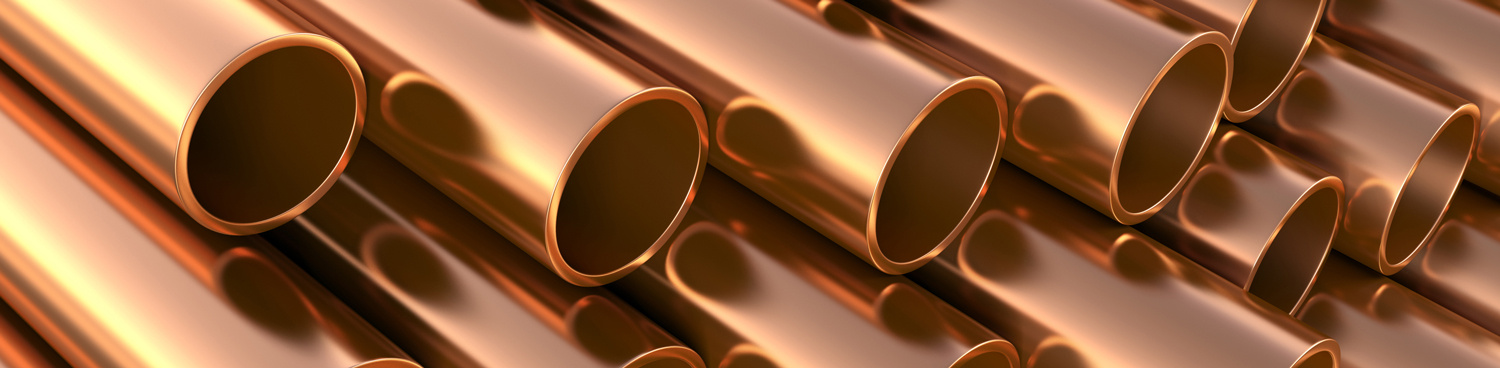

Copper tubes

Copper tubes are used for numerous applications in electronic and household installations due to their excellent heat and electrical conductivity. As cooper is a relatively soft metal, it can also be easily shaped.

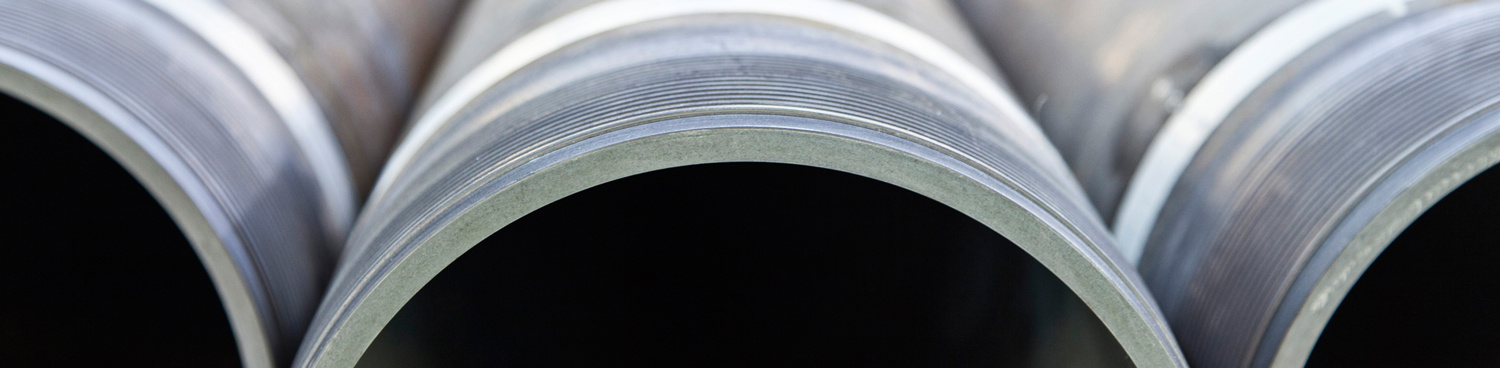

Seamless steel tubes

Seamless steel tubes are primarily used in oil fields and for oil drilling rigs in the oil and gas sector. To produce a seamless steel tube, the pre-tube (bloom) is drawn through a round continuous cast with a hole in one hot molding process.

NFE tube (general)

Non-ferromagnetic tubes such as aluminum and brass tubes have relatively low electric conductivity. Special coils for eddy current testing are required as a result.

FE precision tubes

Precision tubes are produced using a multi-step cold drawing process. These tubes are primarily used in the automotive and medical sectors.

Austenitic tubes

Austenitic tubes, usually made from stainless steel, are easily shaped and highly corrosion-proof. They can also easily be welded and are fire-proof.

Heat exchanger tubes (boiler tubes)

Heat exchanger tubes, also called boiler tubes, are seamless, alloyed steel tubes developed for use at extreme temperatures and pressures. They are primarily used in power plants and petrochemical plants and have a lifecycle of up to 25 years.